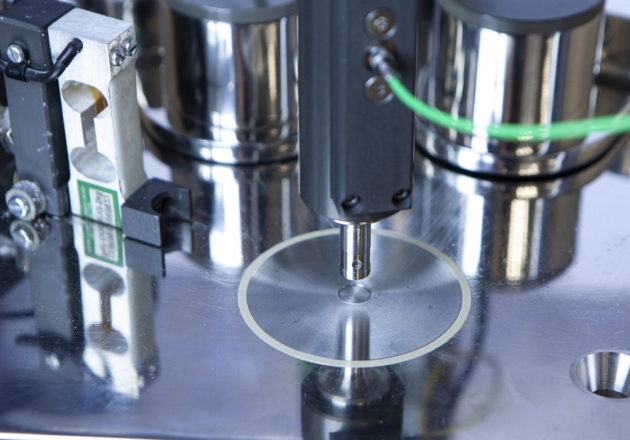

Tablet adhesion often appears unexpectedly at a late stage and can be difficult to solve. Merlin has developed a test to quantify the risk of sticking which we call the “Picking Index”.

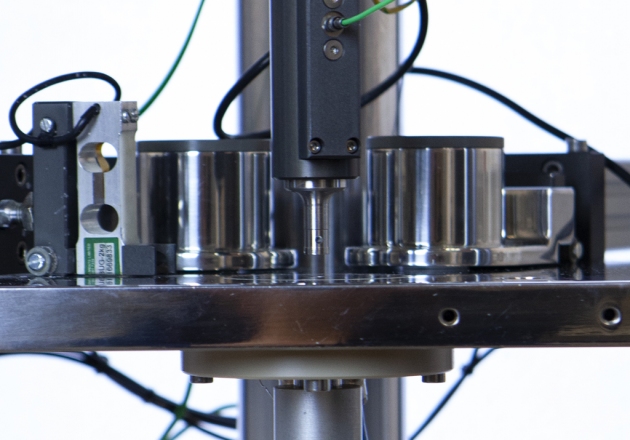

We run tests using our specialist equipment on our compaction simulator to measure adhesion risk and can troubleshoot potential root causes. Merlin can also check the suitability of punch-coating solutions for existing products.