Benefits of Powder Compaction Testing

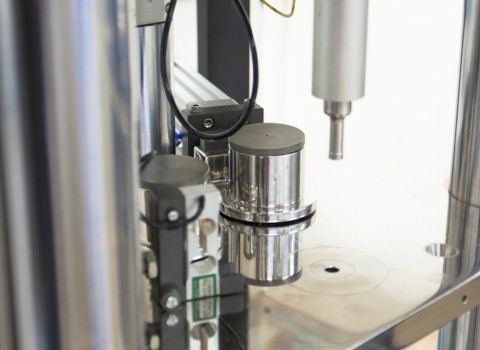

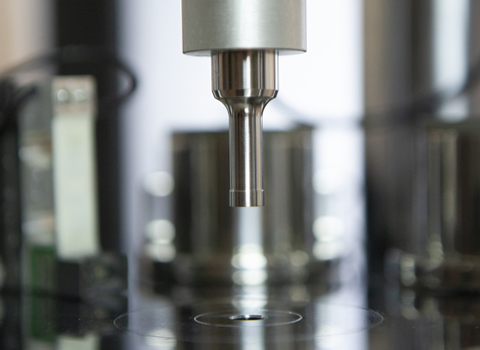

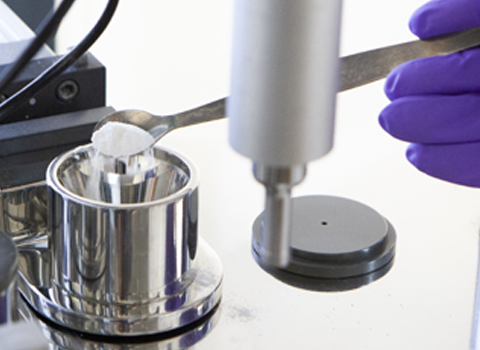

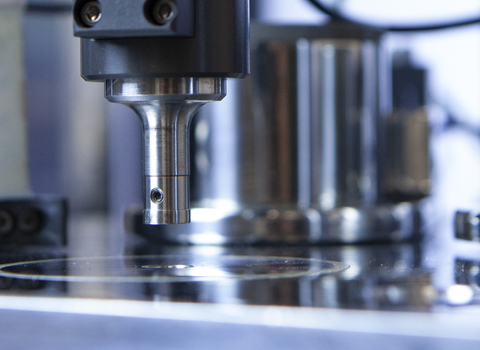

Compaction testing provides valuable information for a range of manufacturing factors. This includes scale-up prediction, lubricant sensitivity, sticking/picking issues and troubleshooting during production. Compaction presses help investigate the compression behaviour of powdered materials which in turn facilitates the design of more robust tablet formulations.

Merlin offers a suite of powder compaction tests. This includes Yield Pressure Determination (Heckel), to identify the key performance characteristics of your API before you start formulation.

Merlin also has a temperature-controlled die that can simulate the real production press operating temperatures (-10⁰C up to 70⁰C). This is key in assessing the impact of temperature on the behaviour of the formulation during compaction and ejection.

In short, compaction testing can:

- Optimial compression force to achieve target strength and hardness

- Reduce risk of defects such as capping and lamination

- Imrpove efficiency and reduce trial-and-error

- Provide insight into powder characterisation to improve manufacturing processes

.jpg)