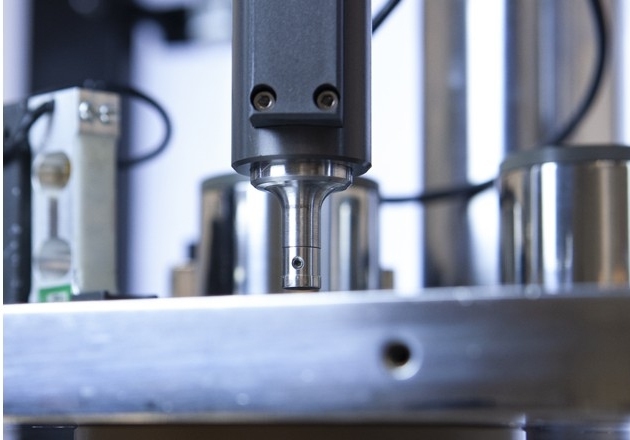

Ejection force measurement is the force measured on the lower punch as the tablet is pushed out of the die at the end of the tablet compression process. The measurement can be used to determine if the optimum amount of lubricant has been added to the formulation.

Avoid Die Wall Adhesion

A tablet formulation will contain a range of materials with different properties. During compression, the formulation is compressed, and the ideal is to have the tablet eject easily, at low ejection forces. Any sticking to the die wall can increase the internal stresses within the tablet and can damage the tablet. The risk of high ejection forces can often be managed by the addition of a suitable lubricant. However, if too much is added, this can affect tablet tensile strength. It is important to have just enough lubricant and optimise the levels.

The tests can be used to quantify the risk of sticking of new formulations or to troubleshoot solutions for existing products.

Tablet Quality

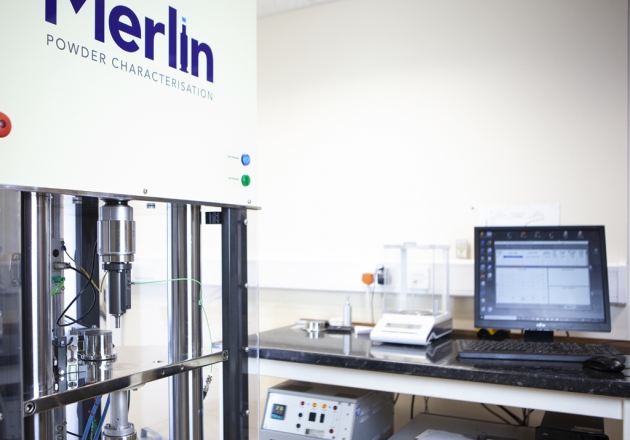

Merlin can accurately measure the ejection forces using standard R&D punches and dies. We can also test with client-provided tooling so that the simulations are as close as possible to real-life production conditions. By assessing different lubricant and blend times it is possible to explore the effect of lubricant and processing conditions on tablet quality.

Merlin can make tablets at low to high speed and low to high force, mimicking the real conditions to measure production-relevant ejection force.

Sometimes, high ejection forces are not due to sticking but are due to radial expansion of the compact. The data produced from testing can determine the factors contributing to high ejection forces which can be mitigated in formulation development.

Ask Us For A Consultation Call

Or you can call us on +44(0)1384 900 265