Tapped density testing is the flowability study of "tapping down” a powder to determine how much it settles during transit. We can run tests to help you understand the tapped density of your powder.

Copley Tapped Density

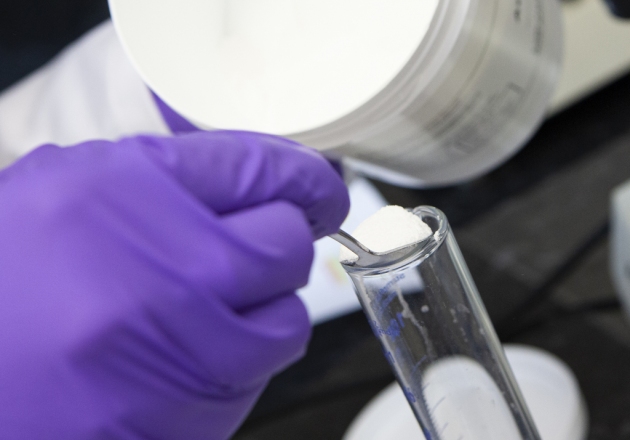

Measuring the powder density once it’s been tapped allows for precise measurement and helps determine the most suitable packaging of the product. This technique is useful for all types of powders and granules, from pharmaceuticals to washing powder. We usually tap the powder for 100 cycles, for example using a Copley Tapped Density Tester.

Using the Copley Tapped Density Tester, the powder is mechanically tapped inside a cylinder until there is no change in the volume of the product.

Related tests we offer our customers include compression science, API characterisation and also bespoke testing.

Calculate Carr's Index & Hausner Ratio

A Copley Tapped Density Tester allows us to work out the tapped density (in grams per ml). To do this, we divide the weight of the sample by the final tapped volume. Using these figures, we are then able to calculate the compressibility index and Hausner ratio to assess the products’ ability to settle.

Compressibility Index calculation (also known as Carr’s Index):

C = 100x (1 – Bulk Density / Tapped Density)

Hausner Ratio calculation:

H = Tapped Density / Bulk Density

Using the two calculations above, we can provide an assessment of the flow characteristics of the powder.

Ask Us For A Consultation Call

Or you can call us on +44(0)1384 900 265