Merlin help by generating compactibility and compressibility results on batches from different years or different campaigns. Measuring the characteristics of the batch will help limit and understand any risks that may occur during manufacture of the final product.

Excipients are one of the ingredients that may be tested for batch-to-batch consistency, this is due to excipients having an impact on the characteristics such as tablet strength. If the quality of powder between batches of excipients starts to change, there can be issues with the final product, so materials need to be closely monitored to check for any changes in characteristics which can cause bigger issues in manufacture. Excipients are important for the function and processibility of formulations. If there are issues with consistency, then there will be significant impacts on the quality and the business.

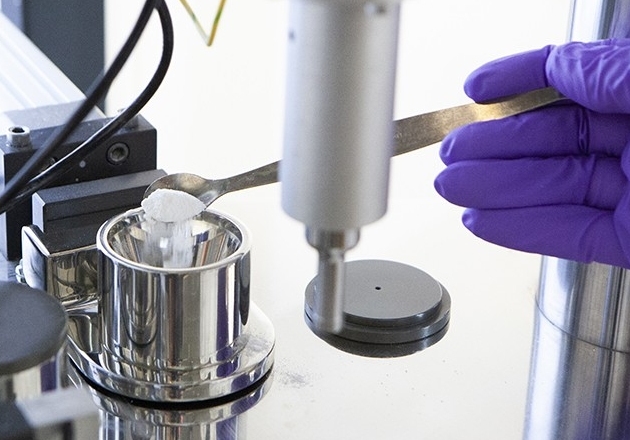

We work with several companies to generate data to give them the key functional information of their powders. We produce this data by using as little as 20g of the material to assess the key functional properties such as yield pressure, compressibility, compatibility, tabletability and true density.