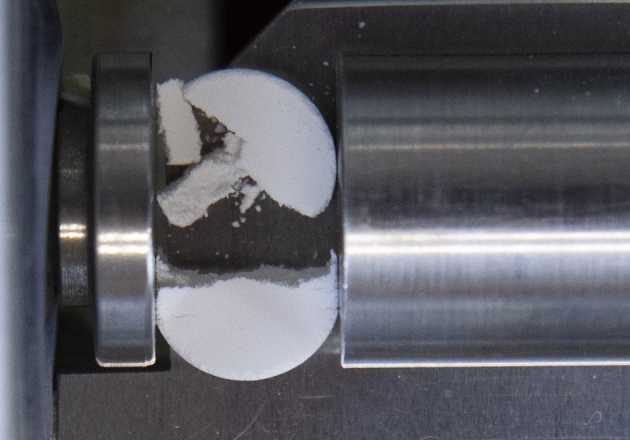

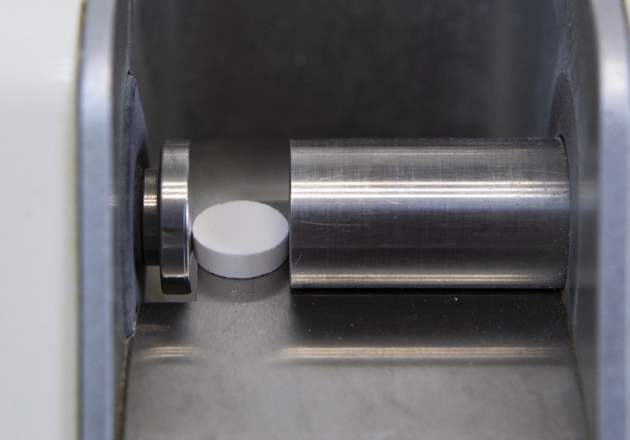

Pharmaceutical tablet hardness testing (or more correctly known as diametral/diametrical crushing strength) is a way of measuring the quality of tablets. Merlin uses tablet hardness testing to calculate the tensile strength of tablets to assess the manufacturability and compactibility of formulations.

This is an add on test for our compaction studies.