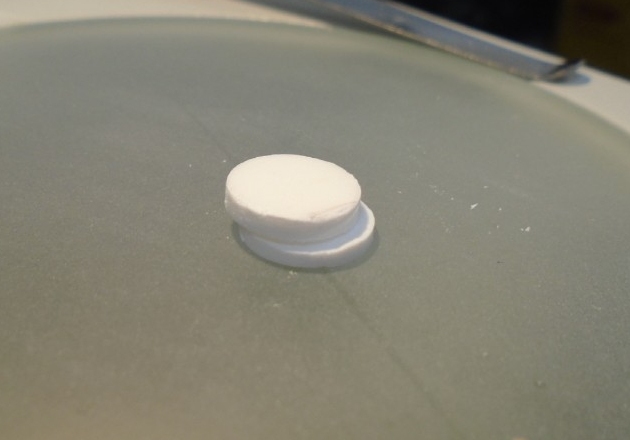

Lamination of tablets happens when the product separates into horizontal layers. Tablet lamination is very similar to capping, but occurs in the main body of the tablet, not at the top, and it can occur immediately after compression or during the storage period.

At Merlin, we can compress your prototype tablet formulations to help you to understand the fundamental compaction properties of your product. Tablet properties at slow speed are not always representative of high speed compression. We can test the formulation at production-relevant speeds to assess the propensity for tablet capping and lamination to de-risk the development and scale-up process.

Depending on the material you want to test and depending on application, we may also recommend compression science and API characterisation, to identify the key characteristics of your material.